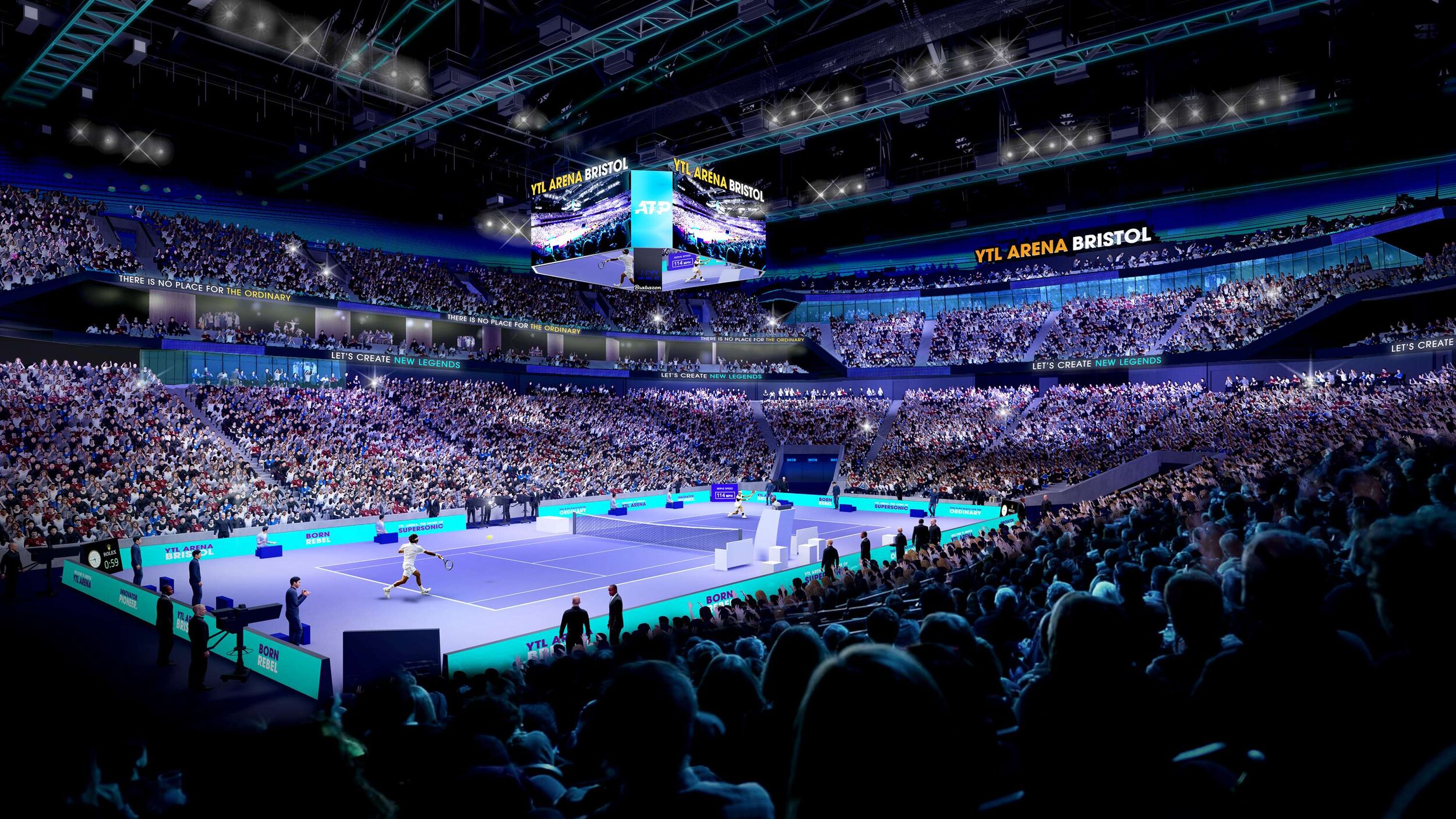

YTL Arena

The exciting new development of a 17,000 seat arena is to be sited within the historic ‘Brabazon Hangars’, adjacent to the 2.5km runway at Filton Airfield in Bristol.

The project looks to retain the existing structures as far as practically possible, maintaining the history and legacy of the site (which produced the British Concord and the Brabazon Bomber planes), whilst transforming the internal spaces into a state-of-the-art, multi-purpose arena with adjoining amenities and exhibition spaces.

The exterior spaces around the hangars will also be developed to create new access into the building, making the arena the focal point of the new Brabazon neighbourhood north of the existing railway line.

OPS believe that the re-purposing and re-use of existing structures is key to the structural engineering industries response to the climate emergency. By re-utilising approximately 5000 tonnes of existing steelwork, we are striving to make the arena one of the most sustainable buildings of its type in the world.

Client: YTL Developments

Location: Filton, Bristol, UK

Architect: Grimshaw

Structural Engineer: OPS Structures Ltd

Completed: Current design project

+ Project overview

Work on the structure has consisted of two broad categories of work; The new arena complex within the hangars is being designed by OPS’s team of experienced stadia and events structure engineers (responsible for other landmark projects such as the Millennium Stadium and Aviva Stadium), alongside Grimshaw Architects. Additionally, the existing structure has been subject to extensive analysis by the OPS team, utilising knowledge of the history of steel design, material testing and detailed finite element analysis.

The new development will see a number of different new structures built inside the existing buildings. The centrepiece of the development is the 17,000-capacity arena which will be located within the central hangar with the adjacent East and West hangars housing a multi-purpose exhibition space and retail opportunities.

To the north of the hangars, a link will be made to the new Brabazon developments and will create the main access way to the Arena. This will include the design of a new bridge over the railway with feature steps and ramp structures to provide access on event day, close to the new North Filton railway station.

+ Designing a new landmark from an existing building

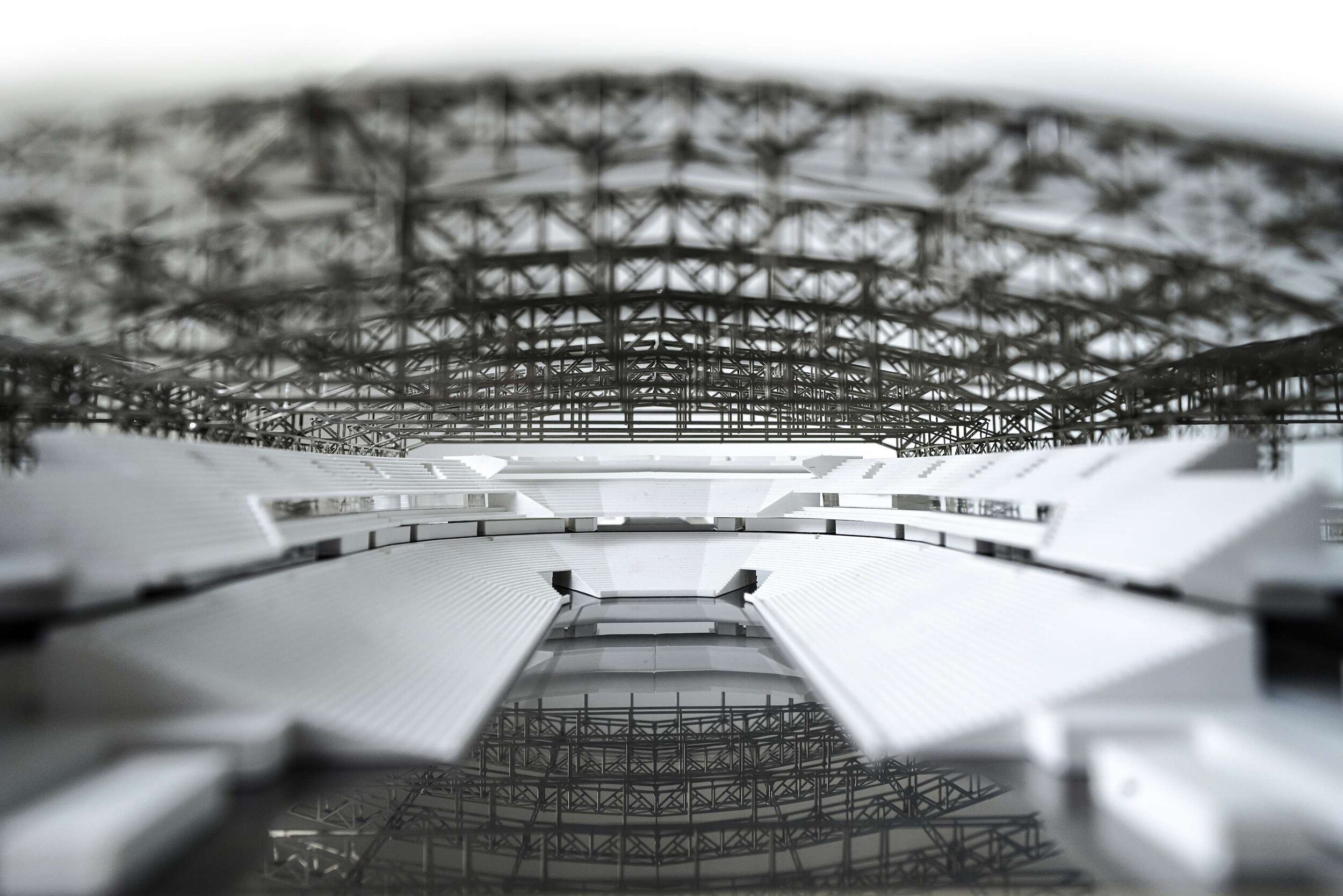

Very few design projects ever truly begin with a blank canvas, but even less ‘new build’ projects begin with an existing structure as vast and impressive as the Brabazon Hangars . Even from a distance, the hangars are incredibly imposing and dominate the surrounding area. Stepping inside the historic space for our initial site inspections, the sense of inspiration was magnified, knowing the history of the engineering feats that were achieved here.

However, after spending a few minutes taking in the structures, the intricate beauty of the 1940’s steelwork became the main focus. The numerous kinks and splices, the thousands of rivets and bolted connections, and the shapes formed out of plates, angles and channels were a reminder of an industrial style lost to time which gives the structure a unique identity.

Our partners at Grimshaw architects and our Client at YTL Developments recognised and shared our passion for the building’s unique identity, and it became clear that retaining as much of the structure as possible was key to the project from an architectural, sustainability and financial perspective.

Through the Brabazon Hangar’s historical association with the Brabazon Mark I, Concorde and the Britannia planes, the hangar was one of the most important hubs of innovation in aviation and engineering advancement in the 20th century. As well as the structure’s historical importance and, as a well-known landmark of Bristol, we know that any alteration to the structure will draw public attention and needs to be carried out in a sympathetic and enhancing manner.

Taking into account the principal of ‘Structural Honesty’ in our work, one of the criteria for our design was to ensure that the steel present on site should be used to its full capacity, which would also save on the carbon and cost of new material. A hybrid system of the existing steelwork and newly designed ‘events trusses’ working to their full capacity in the main hangars ceiling allows for a roof that can support the extensive cladding, acoustic, maintenance, service and rigging requirements of a state of the art arena, with significantly less material than similar buildings.

+ Building an arena for the 21st Century with steel from 1945

At OPS we have a wealth of experience with working on existing structures. Over the years we have developed an in depth understanding of what is required on these types of projects to extract their maximum potential whilst minimising risk. When the hangar was built in 1946 the structure was one of the largest buildings ever constructed in the UK with an enclosed volume of circa one million cubic metres divided up into three interconnecting aircraft hangars. The structure was well-regarded at the time of its construction and was reviewed in a number of architectural publications.

With existing buildings and especially historic buildings which, at the time were considered innovative or unusual, it is essential to understand and appreciate the limitations of the design and construction methods available at that time. Not only may the principle used in the analysis and design of the structure be different to those used today, but the material and construction details used may not meet modern standards.

OPS’s first task after being awarded the position of structural engineers for the project was to undertake extensive analysis of the existing structure. A team led by Mike Stephens tackled the task using four approaches:

- An extensive literature review of drawings and articles, alongside a point-cloud survey of the hangars helped us form an initial 3D BIM model of the structures’ geometry, from which initial work began.

- Understanding of the history of steel design and the techniques, materials and codes available at the time formed the basis of design assumptions regarding elements, connections and calculations. The Dorman Long Handbook, Historical Steel Design Manual and BS 449 were extensively referenced and the question of ‘How many kilonewtons per square meter are in an imperial ton per square foot, again?’ became as common a fixture of the OPS office as ‘How was your weekend?’ or ‘Have you done your timesheet?’

- Material testing of structural elements and fixings were performed to verify and form design calculation assumptions. This required analysis work to identify elements and connections where stresses were low to ensure that the existing structures capacity was not being reduced by extraction of samples for testing!

- Finally, an extensive structural survey was undertaken to confirm that our array of assumptions were representative of what was actually present on site. Using MEWP’s, rope climbers and a spreadsheet big enough to strike fear into the hearts of the most experienced surveyor, OPS-led teams took measurements and photographs of the buildings structure in addition to a condition survey to ascertain the current status of the building structures.